Metal Building Wall Systems

When it comes to choosing a wall assembly for a pre-engineering metal building, selecting the right system can have a significant impact on building performance. The right wall system is often chosen based on desired building use, energy performance, and architectural design. The advantages and disadvantages of each system are discussed below.

The most common wall assemblies are:

Metal panels

Insulated metal panels (IMPs)

Concrete masonry units (CMUs)

Exterior Insulation and Finish System (EIFS)

Tilt wall

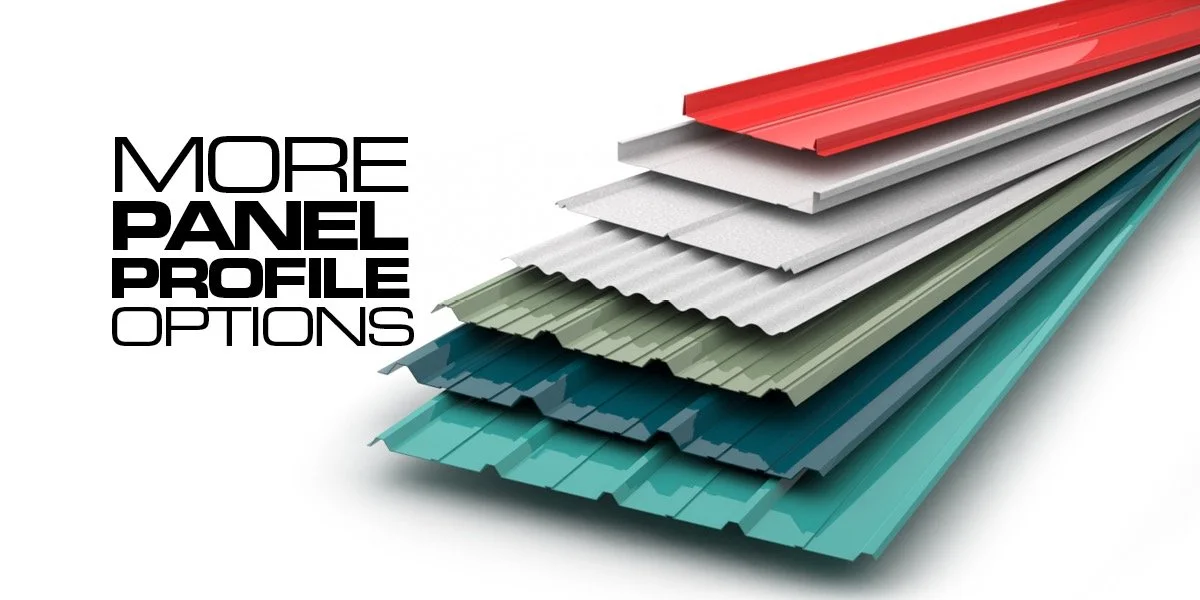

Metal Panels

Metal panels are the most popular choice for pre-engineering metal buildings in commercial, industrial, and agricultural applications. This is due to their durability, ease of installation, and low maintenance requirements. Metal panels are typically attached to the building via girts, but they can also be installed over steel studs. They are available in a variety of colors and finishes and are the least expensive option. However, metal panels are not the best choice for insulation, and they can be noisy during heavy rainfall or hailstorms. In addition, metal panels may dent or scratch, which can detract from their appearance.

Pros:

Most affordable option

25+ year paint warranty

Can handle more framing deflection/sway leading to more affordable steel framing

Cons:

Metal to metal contact with girts/purlins provides very poor insulating value

Difficult to provide adequate air/water sealing, especially around doors and windows

Noise during rain or hail storms can be excessive

Denting or scratching, especially near the foundation, can negatively impact the appearance

Applications:

Agriculture

Commercial

Industrial

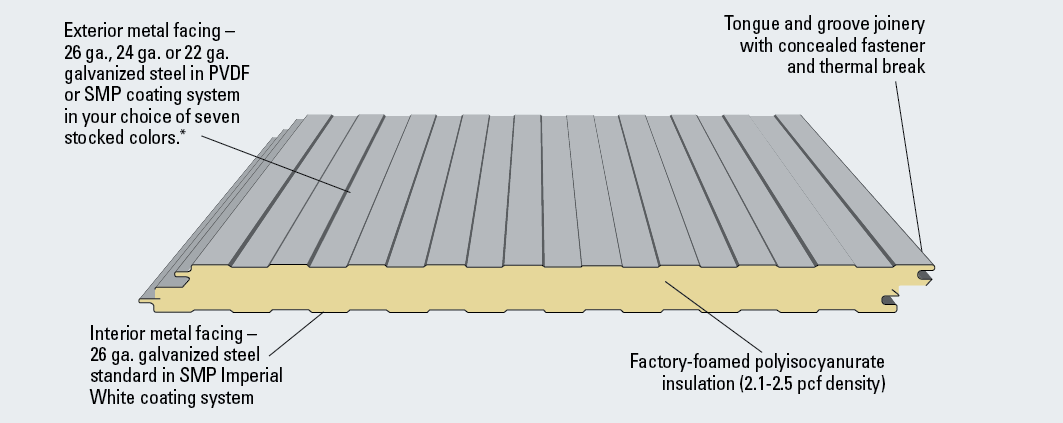

Insulated Metal Panels (IMPs)

Insulated metal panels (IMPs) are similar to metal panels but come with a layer of insulation sandwiched between two metal sheets. This makes them a more energy-efficient option than standard metal panels. IMPs are also durable, low maintenance, and easy to install. However, they can be more expensive than metal panels, and repairs can be more difficult due to their sandwiched construction.

Pros:

Significant improvement in energy efficiency due to improved insulation and air/water sealing

Durable, low maintenance finish with 25+ year paint warranty

Cons:

Significantly more expensive than single skin metal paneling (often 3x-10x more expensive)

More difficult to repair/replace vs single skin metal paneling

Applications:

Climate controlled warehouses

Cold storage used for storage of refrigerated/frozen food

Concrete Masonry Units (CMUs)

Concrete masonry units (CMUs) are blocks made of cement, water, and aggregates like sand or gravel. They are a popular choice for pre-engineering metal building wall assemblies due to their durability, fire resistance, and soundproofing capabilities. CMUs are also available in a variety of finishes, colors, and sizes. However, CMUs are not the best choice for insulation, and they can be heavy, which can make installation more challenging and expensive.

Pros:

Significantly higher durability and resistance to impact damage vs metal paneling

Excellent fire resistance

Excellent soundproofing capabilities

Cons:

Require internal framing in order to provide adequate insulation in climate controlled spaces

Require special foundation detailing due to size and weight

Applications:

Often used as wainscoting in industrial and commercial applications as CMUs are much more resilient if contacted by forklift, trailer, etc.

Applications where improved security is a large concern

Exterior Insulation and Finish System (EIFS)

Exterior Insulation and Finish System (EIFS) is a type of cladding that consists of a layer of foam insulation covered with a textured finish. EIFS framing can also be utilized with metal paneling, hardy plank, etc. in steel homes. EIFS is a popular choice for pre-engineering metal building wall assemblies due to its energy efficiency, versatility, and low maintenance requirements. EIFS also offers a variety of finishes and colors. However, EIFS can be more expensive than other wall assemblies, and it may not be suitable for all climates.

Pros:

High energy efficiency due to air/water sealing around doors/windows

Steel stud framing allows for versatility with locations of doors/windows and interior walls

Cons:

More expensive than metal paneling attached to girts

Textured finish may not be desirable in humid climates, but alternative siding options are available

Applications:

Offices

Retail storefronts

Living spaces

Concrete Tilt Wall

Tilt wall, also known as tilt-up construction, is a construction method where concrete walls are cast on-site and then tilted into place. This method is popular for pre-engineering metal building wall assemblies due to its durability, fire resistance, and soundproofing capabilities. Tilt wall also offers a variety of finishes and can be insulated for energy efficiency. However, tilt wall can be expensive, and the construction process can be time-consuming.

Pros:

Significantly higher durability and resistance to impact damage vs metal paneling

Excellent fire resistance

Excellent soundproofing capabilities

Cons:

Requires specialized construction crew familiar with tilt wall construction

Require special foundation detailing due to size and weight

Applications:

Industrial and commercial applications where resiliency is needed if contacted by forklift, trailer, etc.

Applications where improved security is a large concern

Architectural Examples

Framing

Conclusion

In conclusion, each of these wall assembly options has its own advantages and disadvantages, and the best choice will depend on your specific needs and budget. Metal panels and IMPs are good choices for low maintenance and ease of installation, while CMUs and tilt wall offer durability and soundproofing capabilities. EIFS is a popular choice for energy efficiency and versatility. It's important to consider your project's specific requirements before making a decision.

Cheat Sheet:

Offices

EIFS or stud framing with metal/hardy/wood siding

Stone wainscot with metal siding and girts is also popular in more rural areas

Public Buildings (schools, churches, fire houses, etc)

Offices/classrooms often stud framing with brick/metal siding

Retail Storefront

Stud framing with brick/stone wainscot

Stone wainscot with metal siding and girts is also popular in more rural areas

CMUs

Gymnasiums

Metal siding

Certain municipalities may require stone/brick/cmu front facade or wainscot

Agricultural

Metal siding

Industrial/Warehouse

Metal siding or insulated metal panel

CMUs or concrete tilt wall if additional security is desired

Certain municipalities may require stone/brick/cmu front facade or wainscot

Cold Storage

Insulated metal panels