Framing Basics

When reviewing a quote or discussing your building design with a salesperson, you’ll often hear terms like “clear span”, “flush girts”, and “cable bracing”. Our goal with this page is to provide visual depictions and a brief description to help customer’s visualize their building or determine why certain feature were selected in their design.

Roof Shape

-

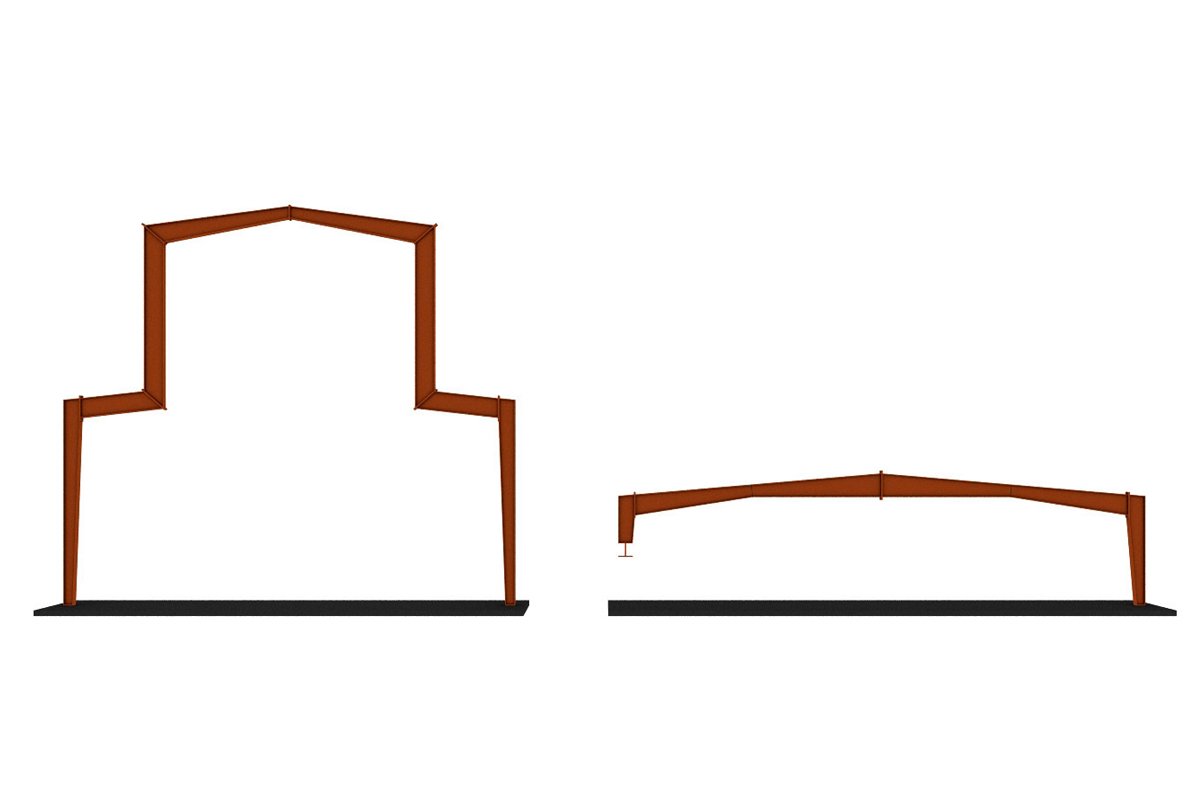

Gable

The most common type of metal building. Typically, lower pitches (1:12 & 2:12) are more economical while higher pitches (5:12 & 6:12) provide more architectural detail (and taller ceilings).

-

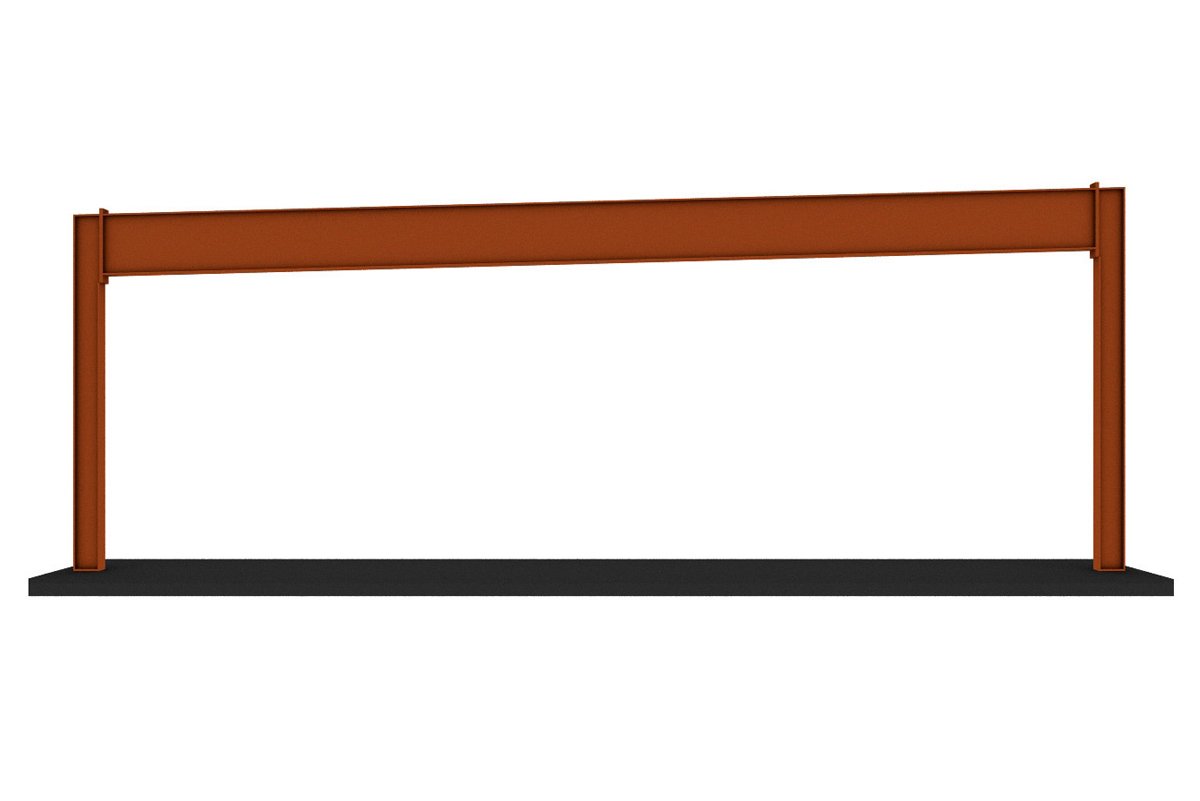

Single Slope

Single slope buildings are often used in commercial storefronts and buildings going for a more modern look.

-

Custom

Clear span monitor barns and gambrel buildings are the two most common type of custom shapes, but the possibilities are nearly endless.

Primary Framing

-

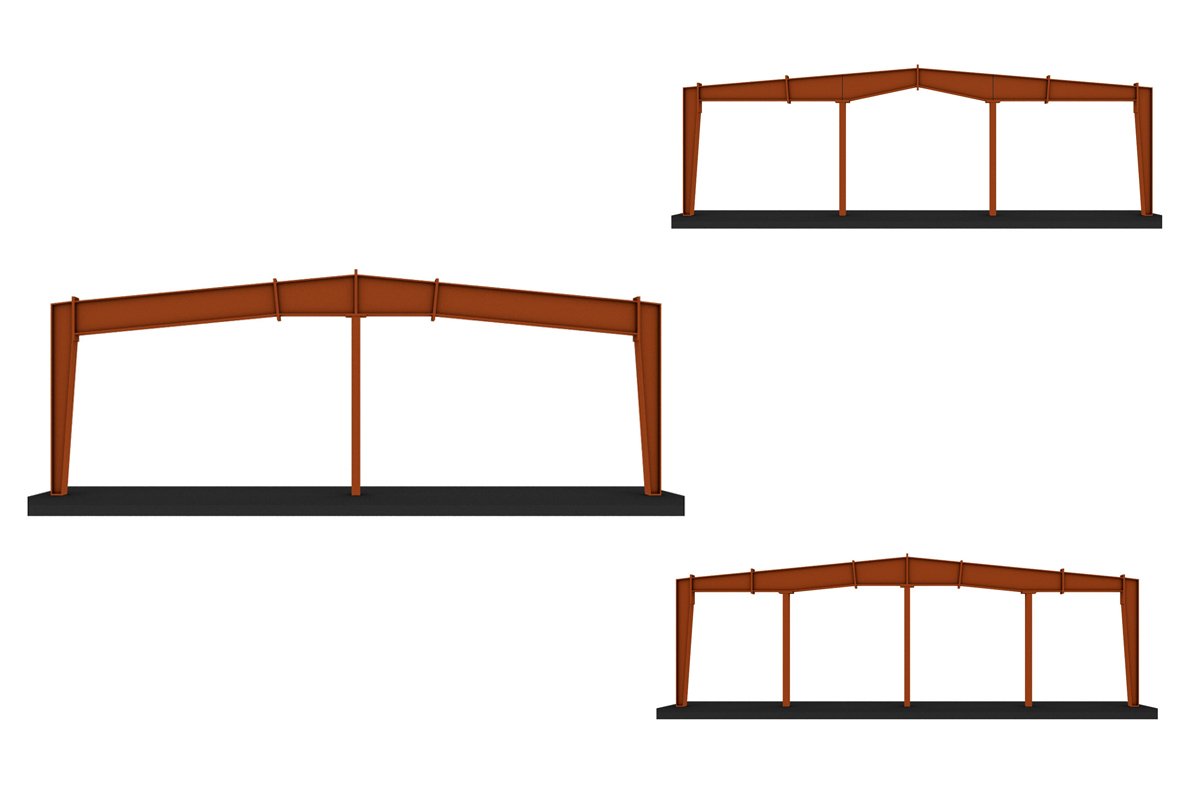

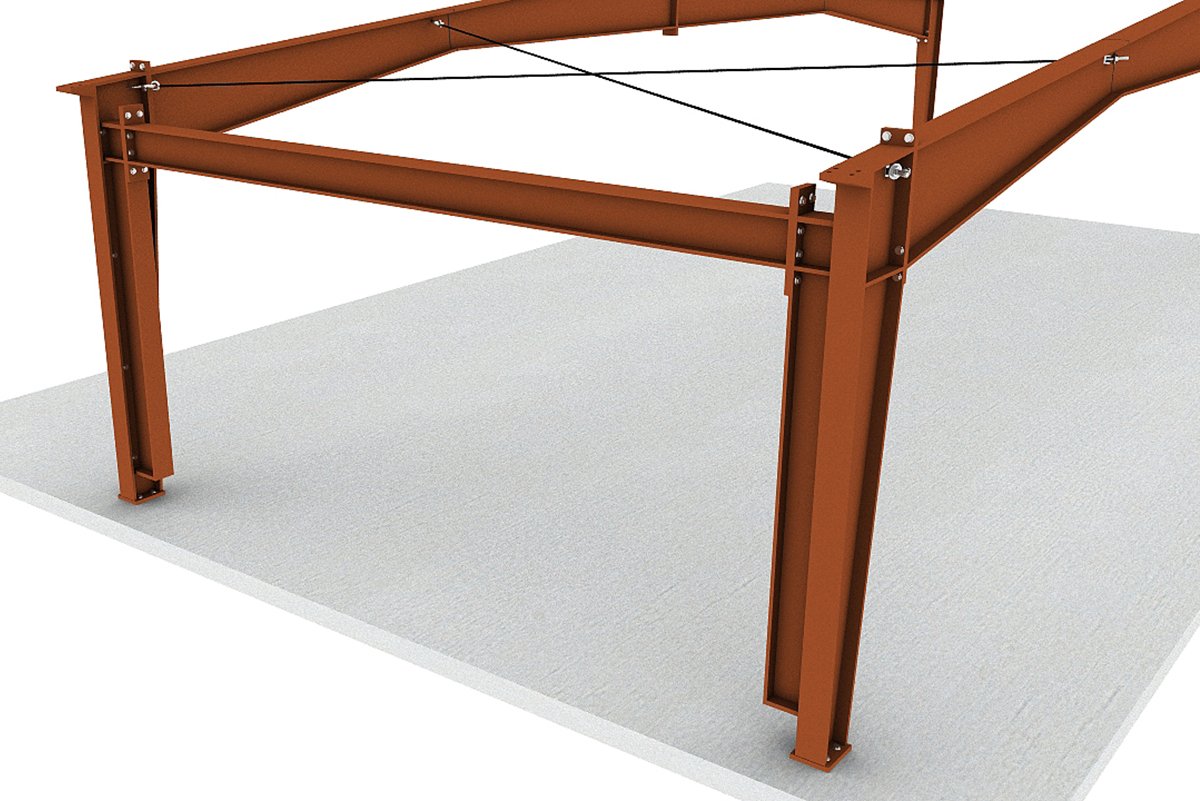

Clear Span

Have the highest amount of usable interior space.

-

Multi-Span

The most economical cost per square foot for buildings over 80′ wide. Ideal design when interior columns will not impact building usage.

Secondary Framing

-

Roof Purlin

Spans between frames and provide surface for mounting roof sheeting

-

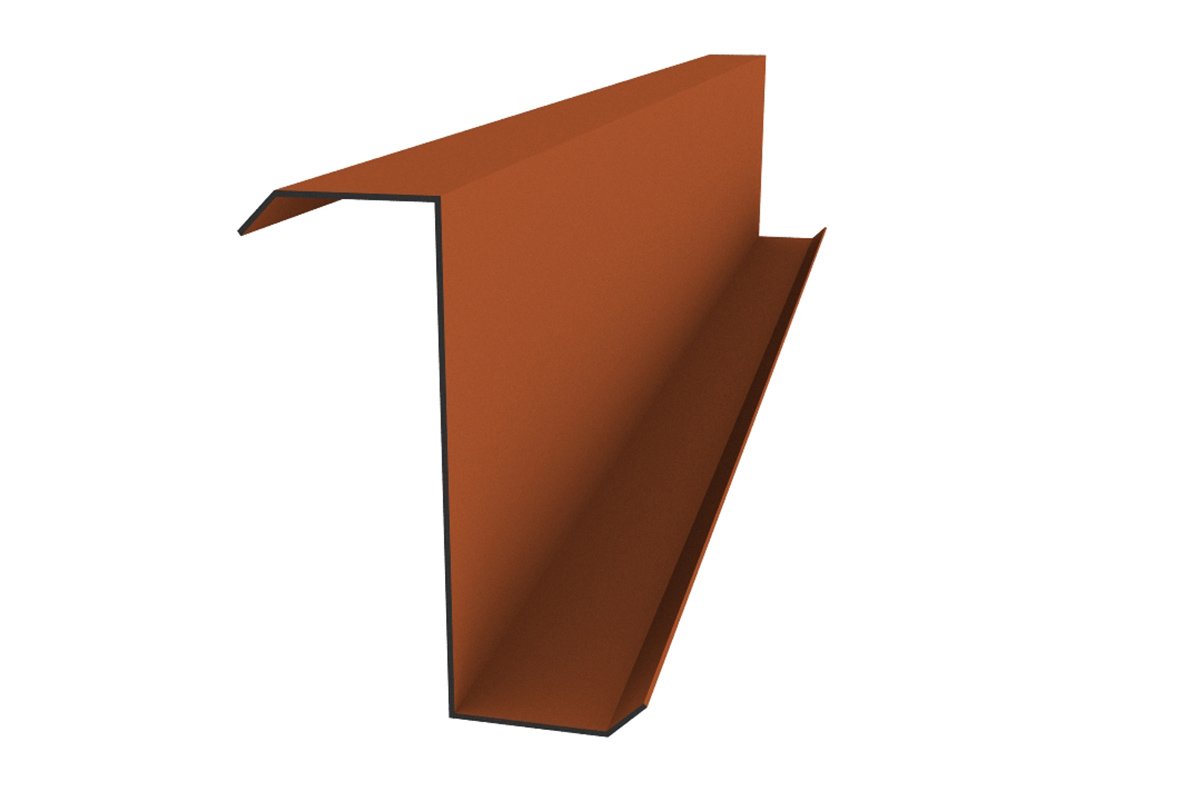

Eave Strut

Spans between frames and provides a surface for the wall sheeting to meet the roof sheeting on the sidewall of a building

-

Wall Girt

Provide structural rigidity of the wall member. Cees are typically used for door openings and zees are used as standard wall members.

Girt Layout

-

Bypass Girt

Girts are attached to the outside of the wall columns. This is the most common layout because it provides additional strength to the girt.

-

Flush Girt

Girts attach between the columns. Flush girts are often used in smaller buildings (<30 ft wide) where space is at a premium and buildings that require an interior build out like offices and barndominiums.

Base

-

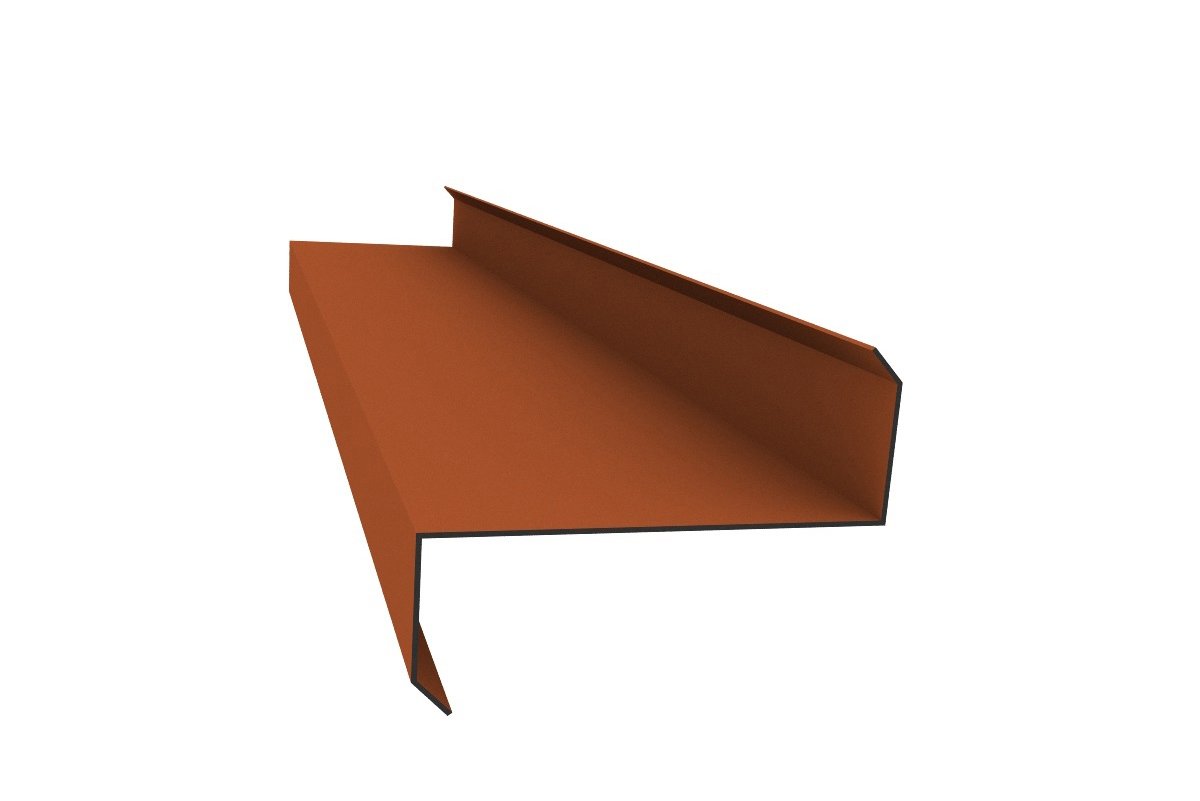

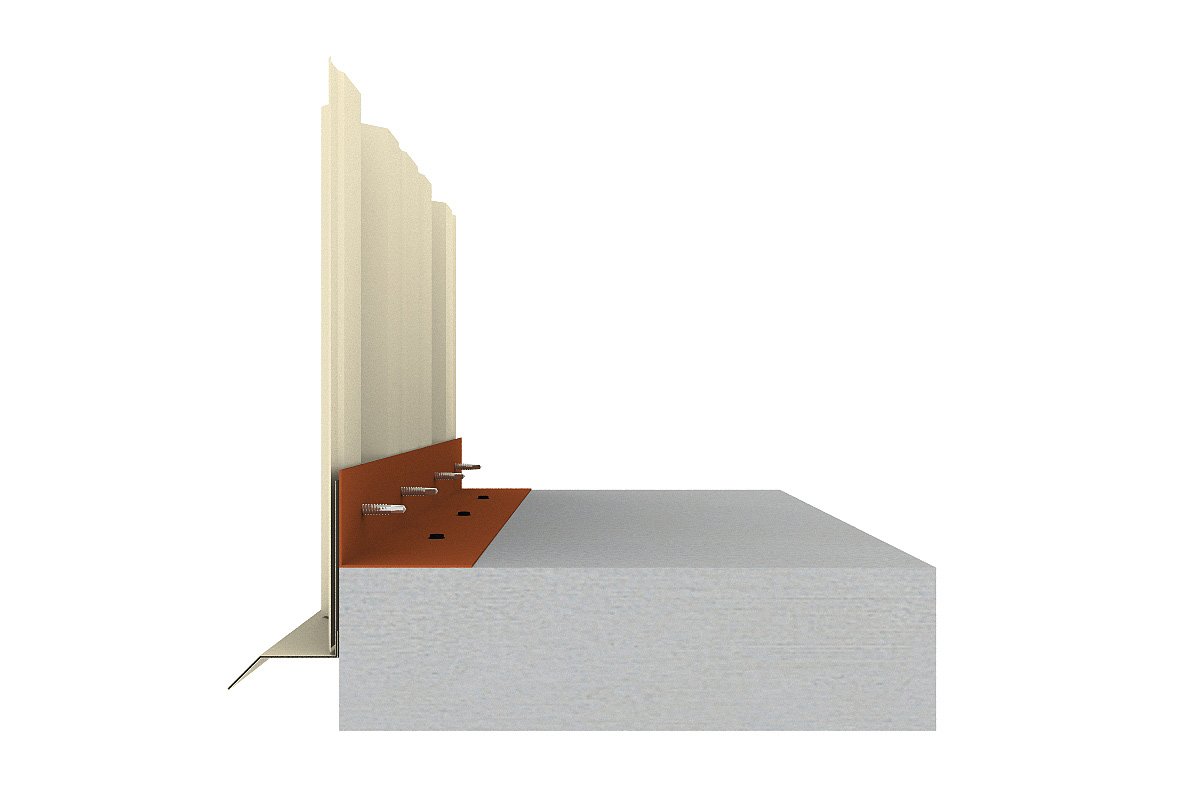

Angle

Angle is the most common way to connect the bottom of the sheeting to the building frame.

-

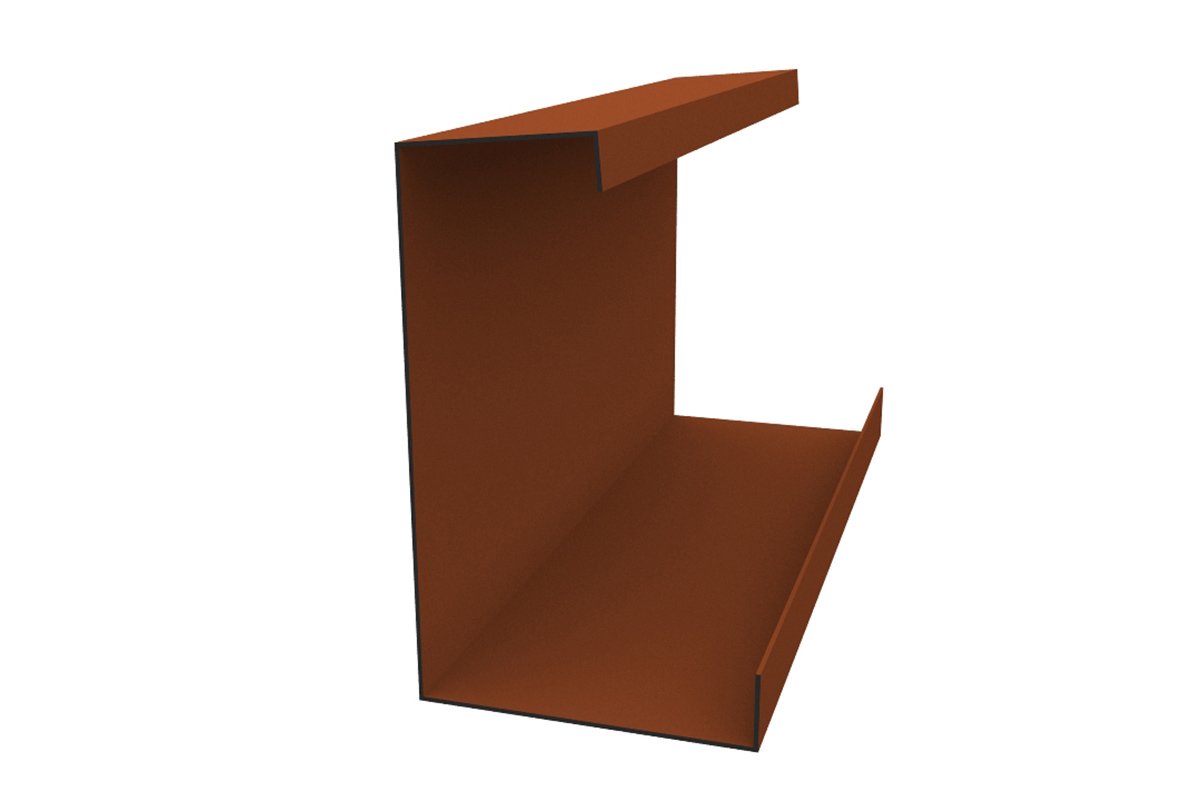

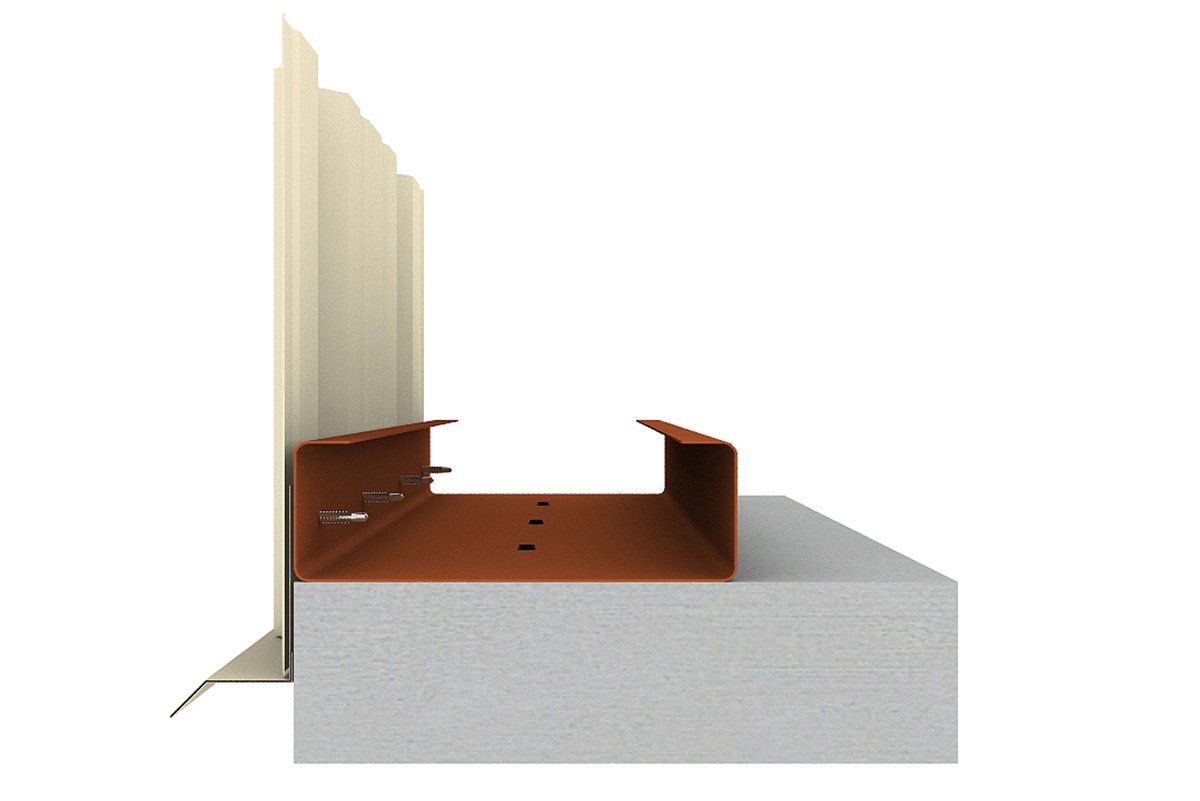

Channel

Channel is used when interior panels will be installed on a building

Wind Bracing

-

X Bracing

The most economical method of bracing used to transfer loads such as wind, seismic and crane thrusts to the foundation. Cables, rods or angles may be used depending upon the design requirements.

-

Portal Frame

Cable bracing alternative on larger buildings when cable “X” bracing is not permitted. Often used when windows/doors are present in every sidewall bay.

-

Wind Columns

Vertical members designed to withstand horizontal wind loads on smaller buildings when cable “X” bracing cannot be used. Often required when windows and/or doors are used in every sidewall bay. They require anchor bolts mounted in the foundation in order to work properly

Architectural Features

-

Interior Studs

This is a common method of building out the interior of a metal building for an office or barndominium.

-

Brick/Stone Wainscoting

A girt is provided midway up the wall to provide the partition between the sheeting and wainscoting. Studs are used to secure the wainscoting to the building.

-

Brick/Hardie/Wood Exterior Walls

Sidewall is open with no girts and wood/steel studs are used to secure the exterior sheathing to the building.

-

Concrete Tilt Wall

Sidewall is open and no girts are provided for concrete tilt walls.