The Only Metal Building Insulation Guide You’ll Need

Are you wondering what options you have to insulate your metal building? This is the article for you. I’m not here to convince you that insulation is the best thing since sliced bread. If you’re still deciding whether or not to insulate your building, check out this article.

This guide will help you answer those questions by discusses the main styles of insulation as well as the pros and cons of each option.

The right metal building insulation for your next project will depend on:

Building location and local building codes

Desired occupant comfort and/or energy consumption

Air/water control

Installation difficulty

Budget

Common Metal Building Insulation Types

Single Layer Fiberglass

High-R Fiberglass

Rigid Foam

Spray Foam

Insulated Metal Panels

Foil Bubble

TLDR Chart

Looking for just a quick overview? The chart below can be used as a quick reference for comparing the various insulation options for metal buildings. In-depth information is provided in the remainder of the article for those who like more information before they make a decision

Single Layer Fiberglass

Single layer fiberglass is the traditional thing that comes to mind when someone says “metal building insulation”. It is a laminated fiberglass insulation that is cut to specific widths and lengths for metal buildings. 4, 5, and 6 ft widths are common. The vapor retarder, which may contain an additional radiant barrier to reflect additional heat, faces the inside of the building. Additional information on vapor retarder options can be found in the appendix.

Single layer fiberglass is Installed between the girts/purlins and exterior metal panel. Each “panel” of insulation is attached to the next “panel” using tabs which are either stapled or taped together.

Advantages

Lowest installed cost per R-value

Easy to install

Sound-absorbing acoustic properties

Enhances light reflectivity

Disadvantages

Does not meet conditioned space requirements in most of the US

R-13 is max recommended with screw down panels to prevent panel protrusion around screws

R-value loss due to thermal bridging and insulation compression

Loss of effectiveness if exposed to moisture

High-R Fiberglass Systems

Gained popularity in order to meet modern energy codes

Consists of fiberglass, a vapor retarder, support banding, and screws

Two main types: Banded Liner and Long Tab

Banded Liner

Unfaced fiberglass, a low permeance fabric which serves as the vapor retarder, and banding that runs both parallel and perpendicular to the purlins. The fabric liner system is installed below the roof purlins, and is supported with metal banding.

Walls

Thermal break tape is installed to the outside face of the girts before the wall panels are installed. The insulation is equal to or slightly greater than the depth of the wall girts. After the wall panels are installed, the unfaced insulation is installed between the girts and are held up by insulation hangers. After that process is complete and the insulation is installed, a fabric liner system is placed over the girts and the insulation.

Roof

The fabric vapor retarder is attached to and completely covers the bottom of the purlins

Once the fabric liner system is installed, the first layer of unfaced fiberglass insulation is installed between the purlins and directly over the liner system. The second layer of unfaced fiberglass insulation is installed perpendicular to and over top of the roof purlins and first layer of insulation. The metal roof is then installed over the second layer of insulation.

Advantages

Low-cost method to meet higher energy codes

Wall panels are quickly installed as insulation is installed after the wall panels

Roof systems often offer fall protection

Attractive finished interior appearance

Reduces thermal bridging by using thermal break tape in walls and thermal blocks in roofs

Disadvantages

Insulation needs to be the same width as the girt/purlin spacing

May require additional girts/purlins to provide uniform spacing

Vapor barrier is not on the ideal side of the wall assembly in hot climates

Installation process is complex

Harder to access girts/purlins for electrical, maintenance and HVAC services

Long Tab Banded Systems

Long tab banded systems are designed for use in roofs only. A long tab system uses two layers of fiberglass insulation (one laminated and one unfaced) and banding that runs perpendicular to the bottom of the purlins. The first layer of faced insulation is installed between the purlins on top of the metal support banding. The second layer of unfaced insulation is installed perpendicular to and over the first layer. The metal roof is then installed directly over the second layer of insulation.

Advantages

Low cost solution for high-R value required projects (R-30 to R-38)

Various facing available (light, medium, heavy, and extreme duty)

Installation from roof deck (no separate liner needed)

Other trades still have easy access to the bottom flange of the roof purlins

Works well with flange bracing

Disadvantages

Bracing interferences (purlin channel bracing, and sag angle bracing) are difficult to work around

More difficult to install than single layer system

Condensation may occur on the bottom of the exposed purlins

Rigid Foam

Rigid foam boards are typically made from polyisocyanurate or polyurethane foam and installed on the exterior of the girts/purlins. The wall and roof panels are installed directly over the rigid board.

Advantages:

Only continuous insulation solution for metal buildings

High R-value per inch

Superior protection against thermal bridging

Easy to install

Best air barrier requirements

Low U-factor (excellent for extreme environments that require robust insulation solutions)

Taped seams provide additional barrier to prevent water from entering building

Acts as a solid roof deck that can aid in installing roofs faster and more safely

Disadvantages:

Expensive option

If left exposed, the material needs to have a class A fire rating in commercial applications

Special conditions on the endlaps for wide buildings

Special eave, rake and base details are required to account for the additional thickness

Spray Foam

Spray foam insulation is typically made from two components, isocyanate and polyol resin, that are mixed together just before application. When they combine, they react and expand rapidly to form foam. This allows it to fill in gaps, cracks, and cavities, creating an airtight barrier. There are two classes of spray foam products: Open-cell and closed-cell foam. Closed cell is typically used in metal buildings, even though it is the more expensive option, because it does not absorb water like the open cell alternative. Spray foam systems are typically installed directly to the inside of metal panels. To preserve panel warranties while allowing for proper thermal expansion, it is typically recommended to apply the spray foam to a separate sheathing/decking, not directly to the back of your metal panels.

Advantages

Easy to install

Closed cell provides additional rigidity to the building

Relatively affordable compared to rigid foam and IMPs

Disadvantages:

May void panel warranties as it can “trap” moisture against panels with exposed fasteners

More expensive than fiberglass

Should not be used as a primary insulation material for standing seam roofs because it restricts roof panel movement

Unsightly appearance when left exposed

Requires paint or will often discolor over time

Insulated Metal Panels (IMPs)

Insulated metal panels are two metal panels that sandwich a rigid foam core (typically polyurethane or polyisocyanurate). Mineral wool is also used as the core insulation material in some IMP products, though rigid foam is more typical. One metal panel provides your exterior finish while the other provides your interior finish.

Advantages

Superior thermal properties

Versatile aesthetic appearance (stucco-look, masonry-look, and flat panel options)

Durability (metal liner won’t tear like fiberglass)

Attractive interior finish

Disadvantages

Highest-cost metal building insulation option

Require heavy machinery during installation due to panel size/weight

Foil Bubble Insulation (aka Reflective Foil)

Foil bubble insulation is a lightweight and waterproof material that helps reflect radiant heat transfer in metal buildings. It’s made from bubble layers sandwiched between layers of foil or plastic.

Advantages

Easy installation

Cost effective

Disadvantages

Very low resistance to thermal transfer (R-1.0 to R-1.3)

Appendix (Nerdy Stuff)

U-Factor (aka U-Value)

U-factor measures heat transfer through an assembly over time. While the R-value measures a single product’s ability to resist heat, the U-factor measures the entire assembly’s resistance to heat transfer. The lower the U-factor, the better the insulation. Mathematically, R-values and U-factors are reciprocals of one another; U-factor = 1/R-value, R-value = 1/U-factor.

R-Value

Insulation R-value tells us how well a material resists heat transfer. Higher R-values mean less heat transfer. R-values for metal building insulation range from R-8 to R-30. The most common fiberglass metal building insulation R-values include:

2” (R-8 before lamination)

3.4” (R-10)

3.7” (R-11)

4.3” (R-13)

5.3” (R-13)

6.3” (R-19)

8.0” (R-25)

9.25” (R-30)

Thicknesses are estimated. Insulation manufacturers produce different thicknesses to meet R-value requirements.

Vapor Retarders

Vapor retarders protect insulation from physical abuse and moisture migration. They also provide a finished interior appearance when interior finishes like drywall, liner panels, etc. are not present. Vapor retarders are available with a radiant barrier to provide additional thermal management.

Standard duty insulation is typically used in applications like warehouses. Specialty facings are available for high-abuse environments like industrial and athletic facilities.

Vapor retarders are typically available in white or black. White facings provide a bright, finished look. Black facings are primarily used for areas such as ceilings where the desire to have the insulation remain unnoticed.

A few factors to consider when selecting a vapor retarder:

Environment: temperature and/or chemical conditions for the application

Permeability: the rate at which water vapor will pass through

Durability: how well it will stand up to physical stress without ripping or tearing

Here’s a brief overview of the most common selections for southern climates

Air Barriers

Air barriers limit air leakage into and out of a building. Uncontrolled air leakage results in increased energy usage due to lost heating or cooling.

Radiant Barriers

A radiant barrier is a foil material. The foil reflects radiant heat away from the interior of the building in the summer months and toward the interior of the building in the winter months. In most metal building applications, radiant barriers are combined with an insulation material, such as fiberglass rolls. Radiant barriers can also be used as a standalone product in non-conditioned buildings, such as garages, storage sheds, barns, and other structures that do not require insulation.

Thermal Breaks and Spacers

Thermal breaks are typically used on exposed fastener (aka screw down) panels. The table below compares the 3 most common types of thermal breaks.

| 1/8" Thermal Break Tape | 1/4" Thermal Break Tape | Sealed N Safe Thermal Spacer | |

|---|---|---|---|

| Thickness | 1/8" | 1/4" | 1" |

| R-Value | R-0.5 | R-1.0 | R-6 |

Thermal blocks are used between a standing seam roof paneling and clip to prevent thermal bridging. There are 3 common thicknesses of thermal blocks: 3/8”, 5/8”, and 1”

Energy Codes

Consult your local building code to verify the U-factor needed for your state.

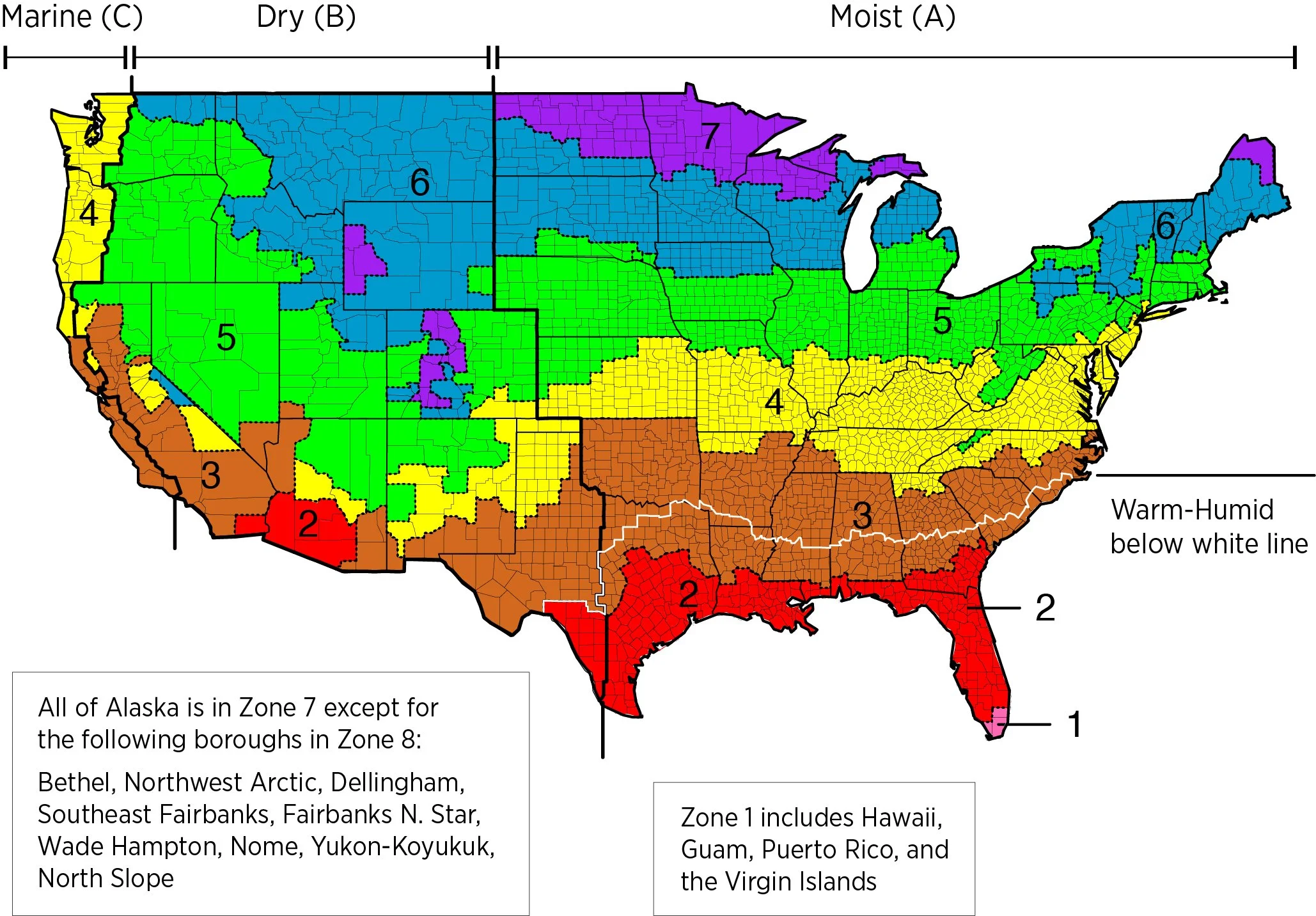

Here’s some basic info on metal building wall assembly U-factors that I’ve collected along the years as well as a climate zone map for reference. I believe that these are from the 2015 editions of the code so if you are reading this in the future, don’t take these as gospel.

Moisture & Fiberglass Insulation

Fiberglass batts are an example of open cell insulation. The woven fiber strands contain hundreds are air pockets that act as an insulator. If the air pockets are filled with moisture, the fiberglass loses its ability to act as an insulator. Fiberglass also loses part of its R-value if it is compressed because there are fewer and fewer air pockets to prevent the flow of thermal energy.

Tips to Improve Your Metal Building Performance

Thermal insulation tape is an affordable way to improve insulation performance

Reduce heat transfer from metal-to-metal contact