Framing Basics

When reviewing a quote or discussing your building design with a building consultant, you’ll often hear terms like “clear span”, “flush girts”, and “cable bracing”. Our goal with this page is to provide visual depictions and a brief description to help customer’s visualize their building and determine which features are right for their project.

Roof Shape

Roof shape has the biggest impact on the look of your structure. Simple gables and single slope roofs are the most common and affordable options. Roof hips, valleys, and combinations of multiple structures are also possible for custom-tailored solutions.

-

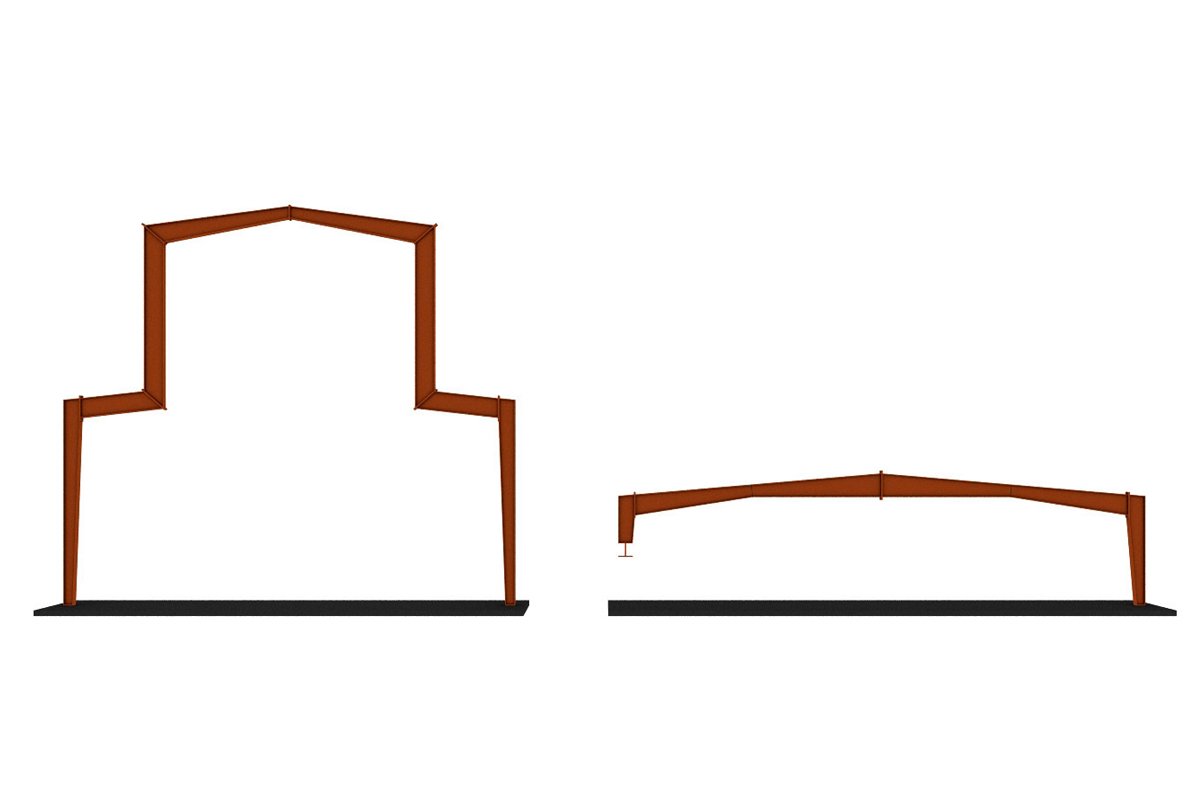

Gable

The most common type of metal building. Typically, lower pitches (1:12 & 2:12) are more economical while higher pitches (5:12 & 6:12) provide more architectural detail and taller ceilings.

-

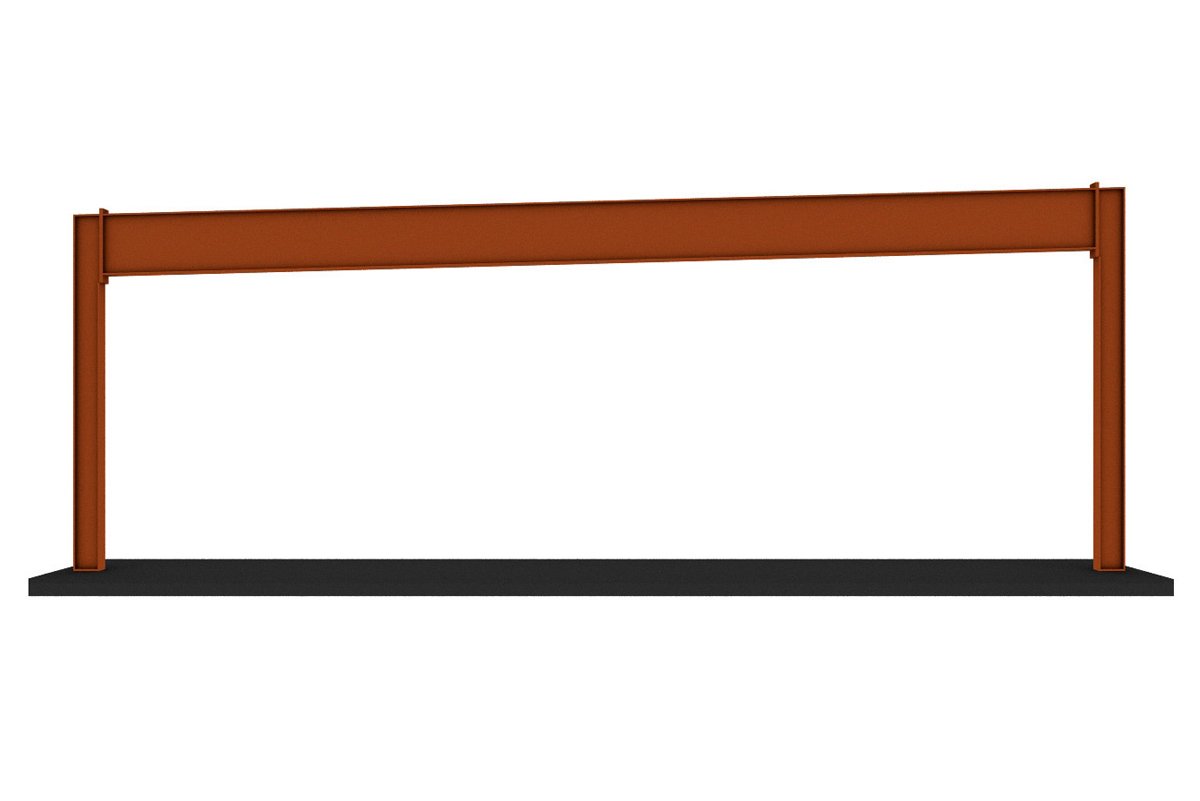

Single Slope

Single slope buildings are often used in commercial storefronts and buildings going for a more modern look.

-

Custom

Clear span monitor barns and gambrel buildings are the two most common type of custom shapes, but the possibilities are nearly endless.

Primary Framing

Primary framing members are the main, load-bearing structural members that define a building’s shape, support its weight, and resist external forces.

-

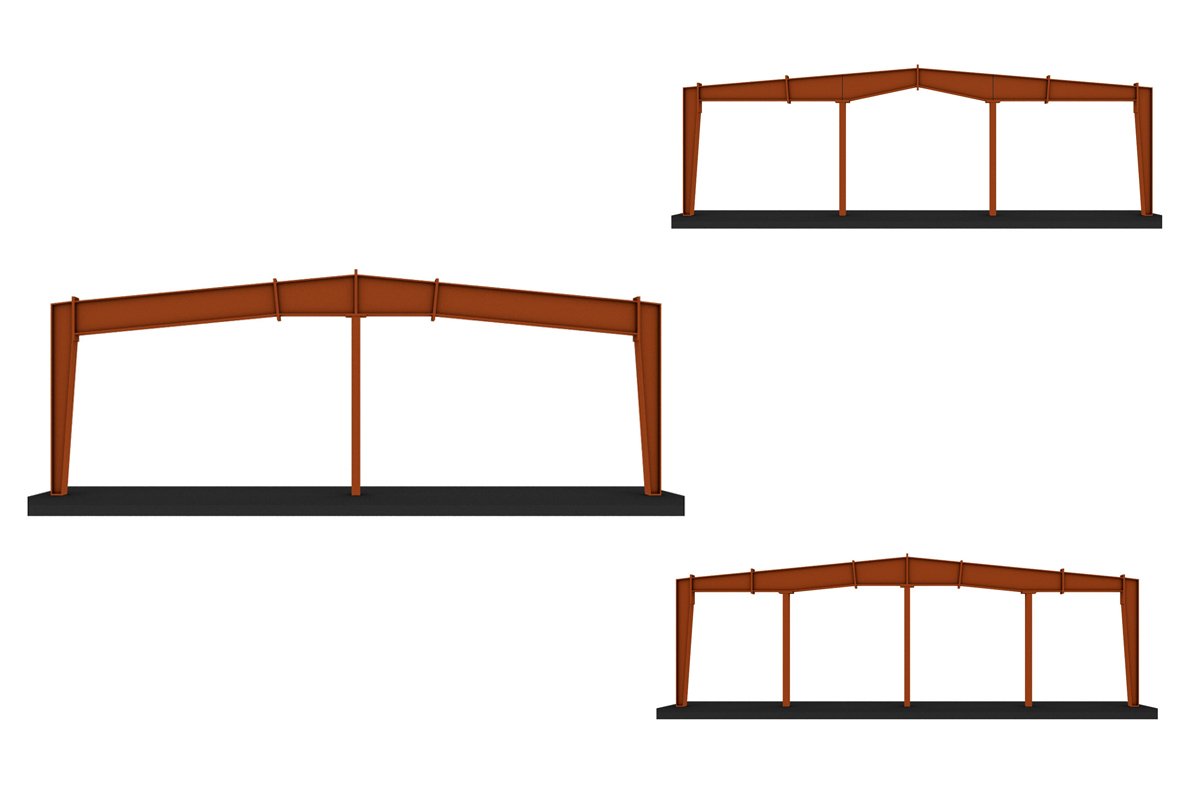

Clear Span

Have the highest amount of usable interior space.

-

Multi-Span

The most economical cost per square foot for buildings over 80′ wide. Ideal design when interior columns will not impact building usage.

Secondary Framing

Secondary framing members provide panel mounting support and transfer environmental loads (wind, snow, seismic) to the primary frames.

-

Roof Purlin

Horizontal roof framing

-

Eave Strut

First girt and last purlin on building sidewall

-

Wall Girt

Horizontal wall framing

Girt Layout

-

Bypass Girt

Girts are attached to the outside of the wall columns. This is the most common layout because it provides additional strength to the girt.

-

Flush Girt

Girts attach between the columns. Flush girts are often used in smaller buildings (<30 ft wide) where space is at a premium and buildings that require an interior build out like offices and barndominiums.

Base

-

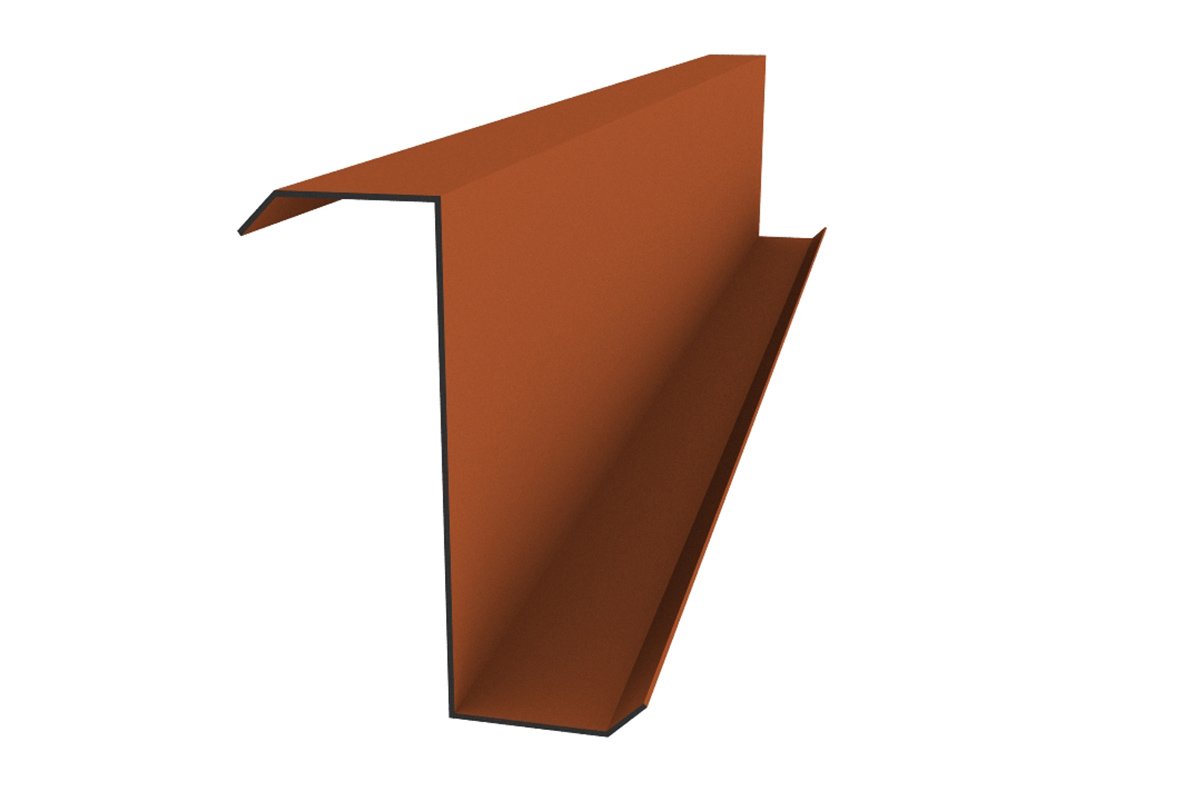

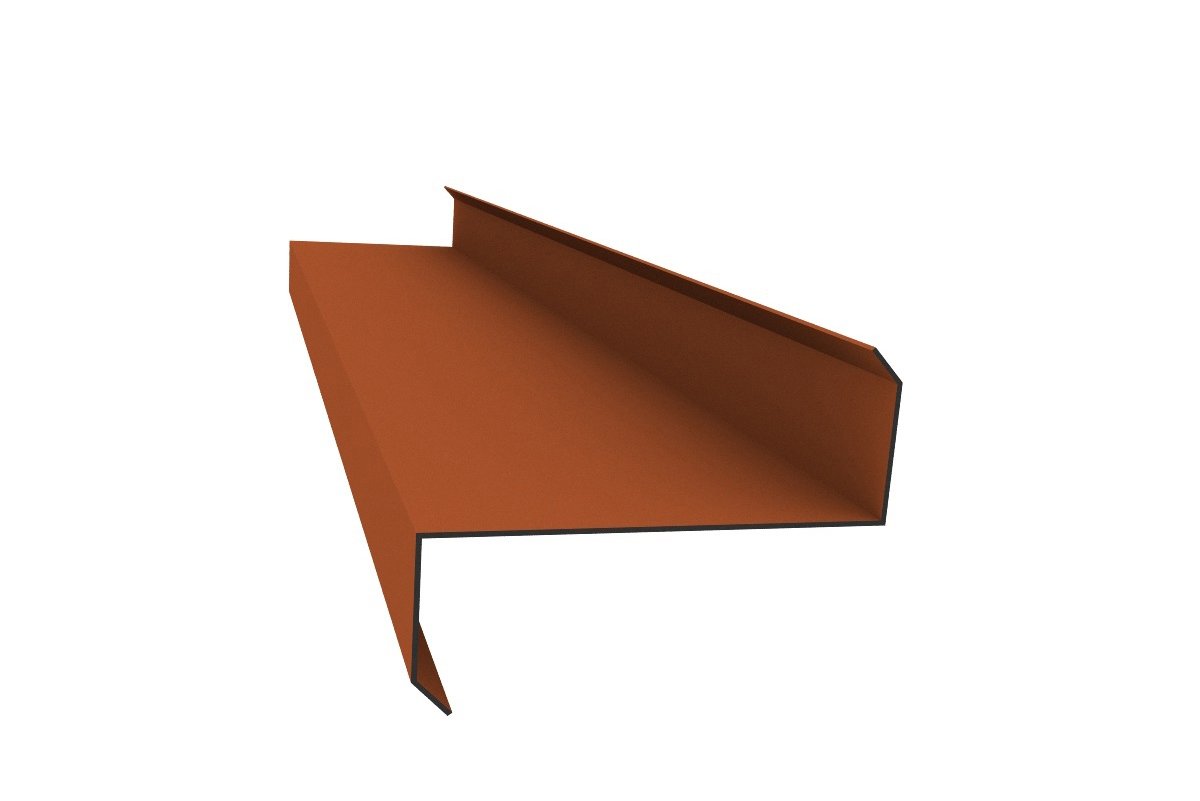

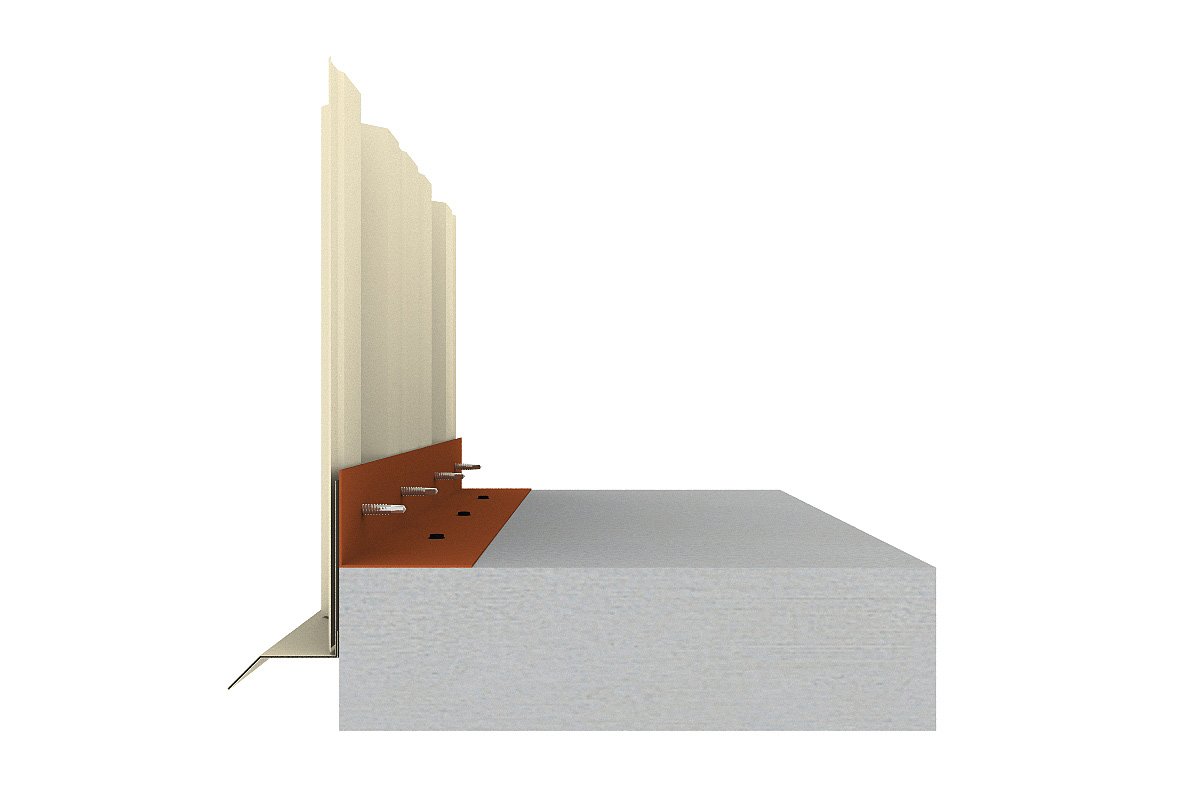

Angle

Angle is the most common way to connect the bottom of the sheeting to the building frame.

-

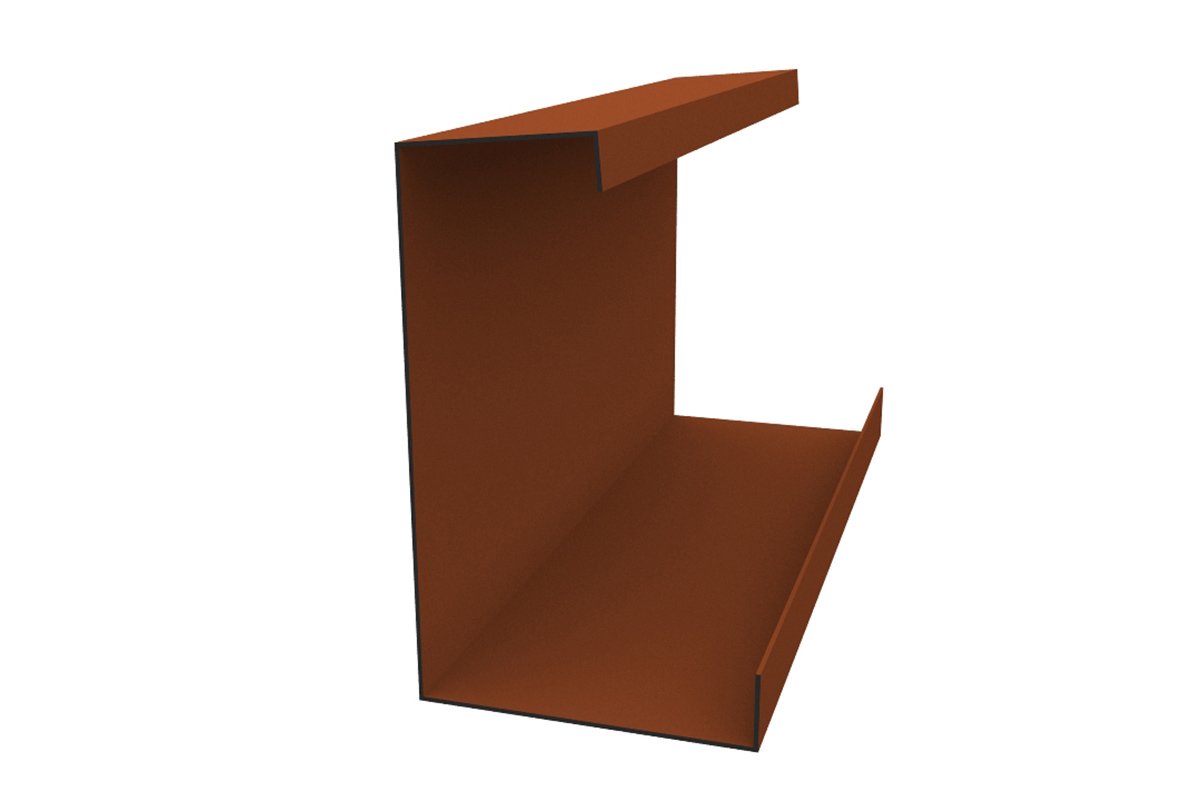

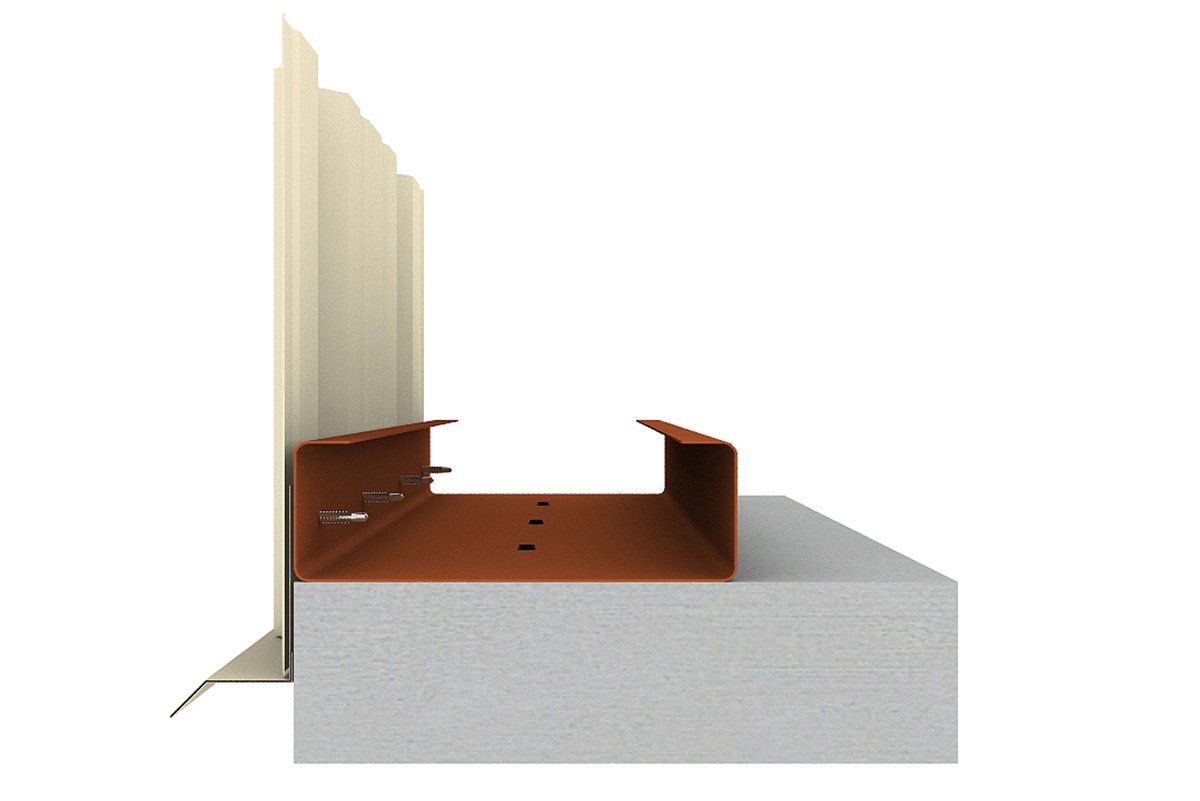

Channel

Channel is used when interior panels will be installed on a building

Wind Bracing

I-beam shapes have a “strong” and “weak” orientation. We need a way to ensure that a building can resist loads in the “weak” direction. That’s where wind bracing comes in. It helps a building resist lateral forces such like wind loads and seismic (earthquake) forces. Wind bracing also helps transfer forces from the structure to the foundation and distribute loads evenly across the frame.

Without bracing, a steel frame can sway or buckle, leading to structural failure under lateral forces.

-

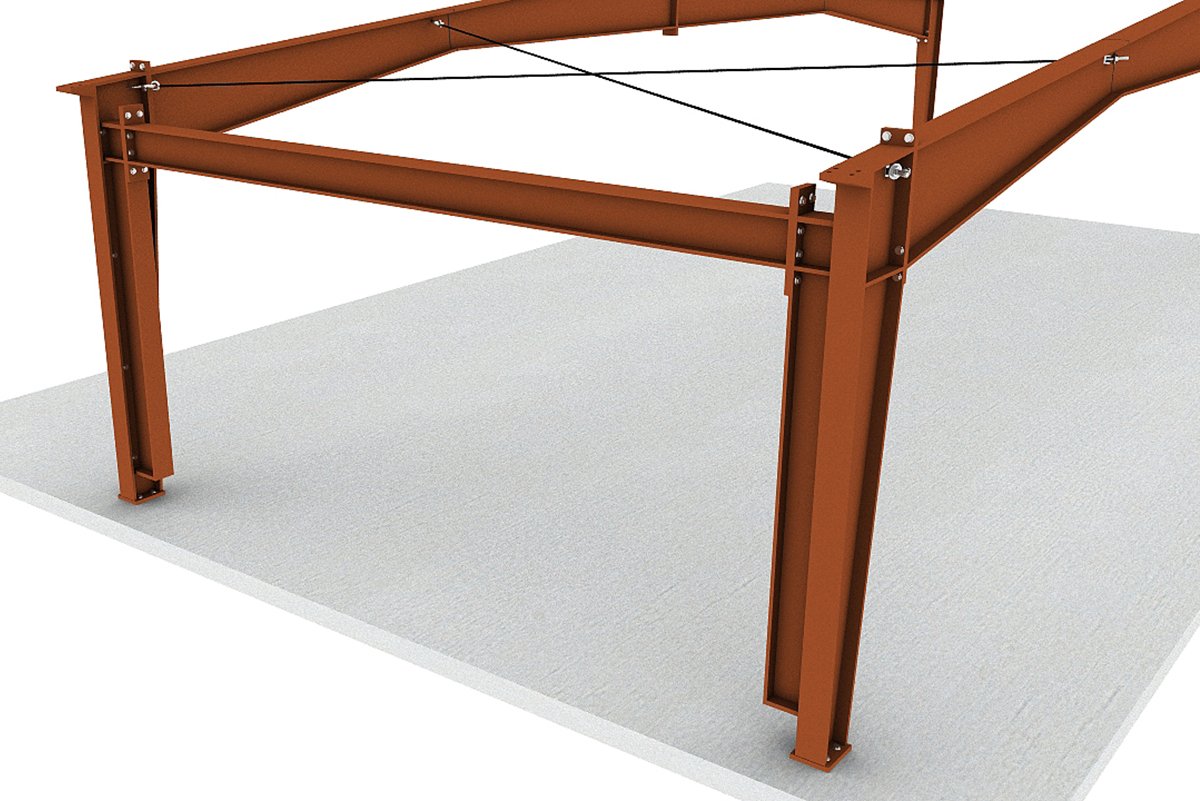

X Bracing

The most economical method of bracing. Cables, rods or angles may be used depending upon design requirements.

-

Portal Frame

Bracing alternative when “X” bracing is not permitted. Often used when windows/doors are present in every sidewall bay.

-

Wind Columns

Designed to withstand wind loads when “X” bracing cannot be used. They are significantly less common because they apply additional loading on the foundation.

Common Wall Framing Options

Metal buildings typically have metal girt framing for warehouses, industrial spaces, etc. Buildings used for homes, offices, and institutional buildings often utilize CMU, steel studs, or tilt walls for additional energy performance, aesthetic appeal, and security. An in-depth look at metal building wall systems can be found here: Metal Building Wall Systems.

-

Exterior Girt, Interior Studs

Sheeting attaches directly to wall girts. Studs mount inside of wall girts. Common method for budget interior build out.

-

Stud or CMU Wainscoting

Studs can help secure the brick/stone wainscoting to a building. CMU is common for to help prevent damage in commercial/industrial settings.

-

Exterior Stud Walls

Studs attach to metal building via spandrel beam/girt. Exterior sheathing is attached to the studs for better air/water tightness. Siding is applied over sheathing.

-

Full Height Tilt Wall or CMU

Sidewall is open. Concrete tilt wall or CMU mounts to metal building spandrel beam/girt for ultimate security and fire resistance.