Metal Building Wall Systems

When it comes to choosing a wall assembly for a pre-engineering metal building, selecting the right system can have a significant impact on building performance. The right wall system is often chosen based on desired building use, energy performance, and architectural design. An in-depth explanation of common wall assemblies is provided below. If you are looking for a quick guide, the conclusion shows common wall assemblies for different types of buildings.

What is a Wall Assembly?

A wall assembly is designed to manage heat flow, air flow, and moisture for our building. Wall assemblies are typically made up of 4-5 components:

Framing

Purpose: Structural support for the wall

Materials: Steel girts, steel studs, wood studs, CMU and tilt wall

Insulation

Purpose: Provides primary thermal resistance

Materials: Fiberglass batts and rigid foam are the two most common choices for a metal building

Notes: Often used with vapor retarder to prevent condensation, incorrect placement can trap moisture

Additional info on metal building insulation can be found here

Sheathing

Purpose: Provides structural racking resistance and a substrate for WRB.

Materials: OSB, plywood, or exterior gypsum

Weather-Resistive Barrier (WRB)

Purpose: Protects building from air, water, and vapor intrusion.

Materials: House wrap (Tyvek), liquid-applied membranes, or integrated sheathing systems (zip sheathing)

Cladding/Siding (Exterior Finish)

Purpose: Provides the first layer of defense against environmental elements (rain, wind, UV)

Materials: Brick, fiber cement, wood, metal panels, or composite siding

What Assembly is Right for My Project?

For high-performance structures, we typically recommend stud framing with sheathing and a WRB. This provides excellent airtightness, moisture management (bulk and vapor), and durability, but it will be slightly more expensive.

If you don’t care about performance (garage, industrial, warehouse), then the good ole metal panel over girts will get the job done for a very affordable price

Here’s a quick overview of some common metal building wall assemblies:

| Cladding/Siding | Wall Framing | Sheathing/WRB | Notes |

|---|---|---|---|

| Metal Panels | Girts (Open Framing) |

None | Poor air & water-tightness Prone to leakage |

| Metal Panels | Studs | OSB, plywood, or gypsum with WRB | Excellent air/water-tightness Higher performance wall assembly |

| Insulated Metal Panels (IMPs) | Girts (Open Framing) |

IMP acts as sheathing, siding & WRB | Outstanding air, water, and thermal performance |

| Concrete Masonry Units (CMUs) | CMU | Often left exposed Spray-on WRB can be applied to resist water intrusion |

Masonry and/or siding can be applied on top Single layer provides durability/security |

| Exterior Insulation and Finish System (EIFS) | Studs | Gypsum with WRB | Excellent thermal performance Occasionally applied over metal panels |

| Concrete Tilt Wall | Concrete Tilt Wall | Often left exposed Spray-on WRB can be applied to resist water intrusion |

Excellent durability and security |

How Are Studs Attached to a Metal Building?

Wall studs typically attach to a spandrel girt (aka spandrel beam) provided by the metal building. This girt helps to transfer the wind load from the wall studs to the metal building framing. Special clips are used to connect the studs to the spandrel girt to the studs. These clips allow for movement between the studs and main building framing to prevent issues with binding during deflection, differential thermal expansion, etc.

Common Metal Building Siding and Framing

Metal Panels

Metal panels are the most popular choice for in commercial, industrial, and agricultural applications. They are affordable, durable, easy to install, and require little maintenance. Metal panels are typically attached to the building via girts, but they can also be installed over steel studs and sheathing. There are two main types of metal panels available: exposed fastener and concealed fastener.

Exposed Fastener Metal Panels

Screws with rubber washers attach the panel to the framing

Common types: PBR, PBU, PBC, Ag

Concealed Fastener Metal Panels

Fasteners are hidden behind interlocking seams

Common types: Masterline 16 and 12” Flat Panel

| Concealed Fastener Panels | Exposed Fastener Panels | |

|---|---|---|

| Aesthetic | Clean, modern, look | Industrial appearance |

| Weather Resistance | Excellent | More prone to leakage |

| Material Cost | Higher (24ga Standard) | Lower (26ga Standard) |

| Installation Time | Slower, more technical | Faster, simpler |

| Durability | Denting/scratching near foundation is common | Denting/scratching near foundation is common |

| Maintenance | Very little | Screws replaced over time |

| Attachment | Most common over studs w/ sheathing | Most common over girts (open framing) |

Most Common Use Cases

Concealed fasteners: High-end commercial buildings, rainscreen facades, architectural features

Exposed fasteners: Warehouses, agricultural buildings, or budget-driven projects

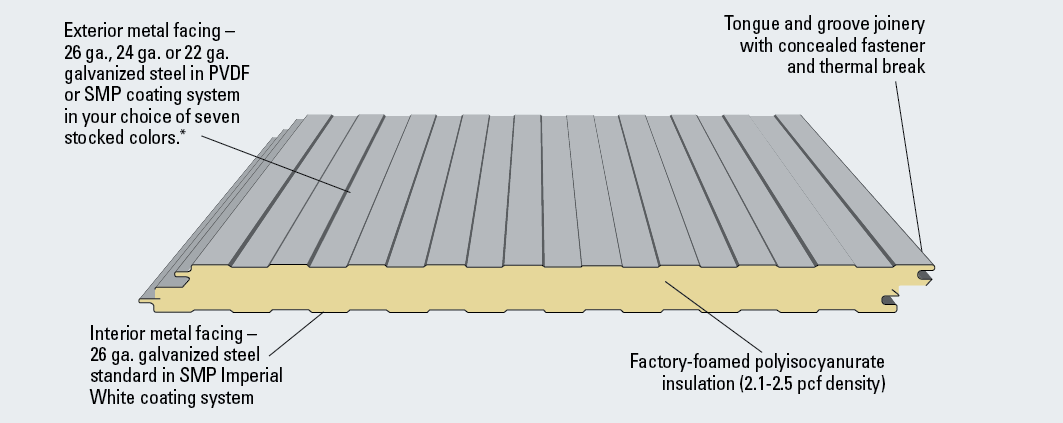

Insulated Metal Panels (IMPs)

Insulated metal panels (IMPs) are similar to metal panels but come with a layer of insulation sandwiched between two metal sheets. This makes them a more energy-efficient option than standard metal panels. IMPs are also durable, low maintenance, and easy to install. However, they can be more expensive than metal panels, and repairs can be more difficult due to their sandwiched construction.

Pros:

Significant improvement in energy efficiency due to continuous insulation and air/water sealing

Cons:

More expensive than single skin metal paneling (often 3x-5x more expensive)

More difficult to repair/replace vs single skin metal paneling

Applications:

Climate controlled warehouses

Cold storage used for storage of refrigerated/frozen food

Attachment:

Attach to metal building girts

Concrete Masonry Units (CMUs)

Concrete masonry units (CMUs) are blocks made of cement, water, and aggregates like sand or gravel. They are durable and fire resistance. CMUs are also available in a variety of finishes, colors, and sizes.

Pros:

Significantly higher durability and resistance to impact damage vs metal paneling

Excellent fire resistance

Cons:

Require internal framing to provide adequate insulation in climate controlled spaces

Require special foundation detailing due to size and weight

Applications:

Often used as wainscoting in industrial and commercial applications as CMUs are much more resilient if contacted by forklift, trailer, etc.

Applications where improved security is a large concern

Attachment:

Attach to metal building spandrel girts

Exterior Insulation and Finish System (EIFS)

Exterior Insulation and Finish System (EIFS) is a type of cladding that consists of a layer of foam insulation covered with a textured finish. EIFS provides high energy efficiency and finish versatility. It is expensive than other wall assemblies and may not be suitable for all climates.

Pros:

High energy efficiency due to air/water sealing around doors/windows

Steel stud framing allows for versatility with locations of doors/windows and interior walls

Cons:

More expensive than metal paneling attached to girts

Textured finish may not be desirable in humid climates, but alternative siding options are available

Applications:

Offices

Retail storefronts

Living spaces

Attachment:

Metal studs attach to metal building spandrel girts

Some EIFS systems attach directly over metal panels

Concrete Tilt Wall

Tilt wall construction casts concrete walls on-site before tilting them into place. Tilt walls are most often seen with a standard joist and decking with interior column arrangement, but they are also used in metal building wall assemblies that require the durability, fire resistance, or security of a concrete wall. Tilt wall also offers a variety of finishes and can be insulated for energy efficiency. However, tilt wall can be expensive, and the construction process can be time-consuming.

Pros:

Significantly higher durability and resistance to impact damage vs metal paneling

Excellent fire resistance

Excellent soundproofing capabilities

Cons:

Requires specialized construction crew familiar with tilt wall construction

Require special foundation detailing due to size and weight

Applications:

Industrial and commercial applications where resiliency is needed if contacted by forklift, trailer, etc.

Applications where improved security is a large concern

Attachment:

Attach to metal building spandrel girts

Conclusion

The best wall assembly for your project depends desired building performance/longevity and budget. Stud framing provides the highest performance option along with nearly unlimited siding options. Girt framing is a great choice for a those balling on a budget or applications that aren’t climate controlled.

Cheat Sheet:

Homes & Barndominiums

Framing: Wood stud (preferred), steel girt (budget)

Sheathing: OSB/plywood (preferred); none (budget)

Insulation: Continuous or stud infill; compressed between girts/panels (budget)

Siding: Metal, hardy, masonry, or wood depending on budget/aesthetics

Offices

Framing: Metal stud

Sheathing: Exterior gypsum

Insulation: Continuous or stud infill

Siding: Metal, hardy, masonry, or wood depending on budget/aesthetics

Stone wainscot with metal siding and girts is also popular in more rural areas that aren’t concerned with code compliance

Public Buildings (Schools, Churches, Fire Houses, etc.)

Framing: Metal stud or CMU

Insulation: Continuous or stud infill

Sheathing: Exterior gypsum

Siding: Metal, hardy, masonry, or wood depending on budget/aesthetics

Retail Storefront

Framing: Metal stud or CMU

Insulation: Continuous or stud infill

Siding: Metal, hardy, masonry, or wood depending on budget/aesthetics

Gymnasiums

Framing: Steel girt or metal stud

Insulation: Compressed fiberglass, full-depth fiberglass

Siding: Metal, hardy, masonry, or wood depending on budget/aesthetics

Agricultural

Framing: Steel girt

Siding: Metal paneling

Industrial/Warehouse

Framing: Steel girt, CMU, or tilt wall

Siding: Metal panels, insulated metal panels

Certain municipalities may require stone/brick/cmu front facade or wainscot

Cold Storage

Framing: Steel girt

Siding: Insulated metal panels

I updated this with some additional info on 5/25/25. -NR