Metal Building Walk Door Guide

Walk doors (aka man doors or personnel doors) provide secure and convenient access to your building. This article outlines the different types and styles of walk doors commonly used in metal buildings.

Choosing the Right Walk Door

Things to consider for your metal building walk door:

Intended use (public access, employee-only, emergency exit)

Security needs (lock systems and reinforced frames)

Walk Door Size

Walk doors for metal buildings are available in both single and double door options.

Single Walk Doors

Standard widths: 3’-0” and 4’-0”

Standard height: 7’-0”

Double Walk Doors

Two adjacent walk doors operated independently or together.

Standard width: 6’-0”

Standard height: 7’-0”

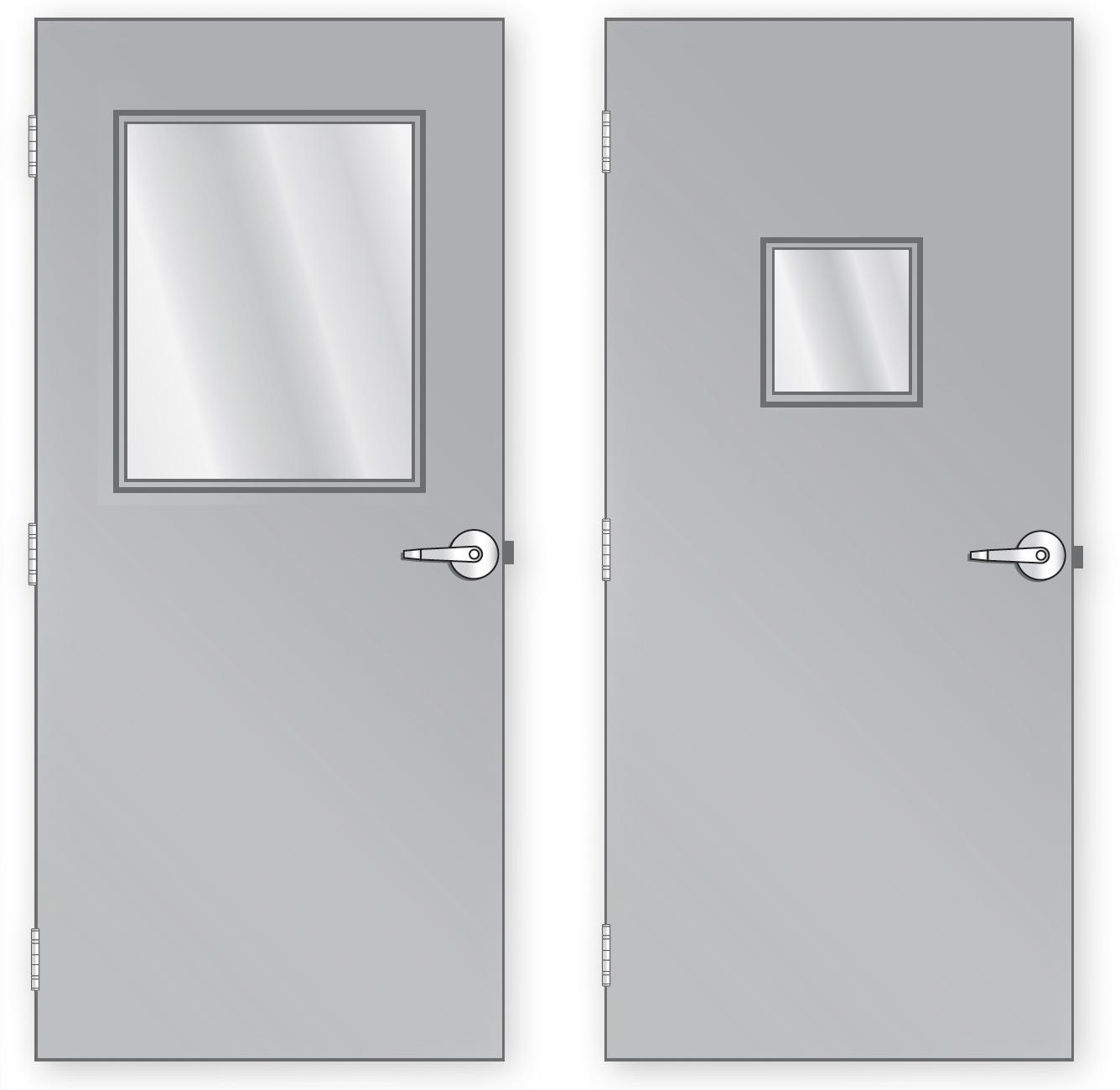

Walk Door Lite Kits (Windows)

These doors incorporate glass panes in the door for additional light or to improve visibility for safety.

Glazing Options: Clear, frosted, tempered, or insulated glass

Common Sizes: 12”x12” (Vision Lite), 8”x30” (Narrow Lite), 24”x30” (Half Glass), 24”x60” (Full Glass)

Door Material Options

Steel Doors

Most common material for metal building systems

Door

Heavy Duty: 18 gauge

Standard Duty: 20 gauge

Frame

Heavy Duty: Welded frame, 16 gauge thickness, interlocking mitered-corner connection

Standard Duty: Bolted frame, 16 gauge thickness

Subjambs

16 gauge subjamb

Insulation Core

Polystyrene R-6.6 (U = .15) or Polyurethane R-11.1 (U = .09)

Hinges

Heavy duty: Ball bearing hinges with security non-removable pins

Standard duty: Plain bearing hinges

Mounting Clips

12 gauge adjustable clips to attach to frame to the girt and floor

Paint Finish

Baked-on primer

Gray, white, and bronze are the most common colors

Stainless Steel Doors

Excellent strength and durability

Corrosion, fire, and impact resistant

Ideal for high-traffic areas and environments that require stringent hygiene standards

Wood Doors

Interior wall applications

Solid core pre-finished door with embossed oak veneer finish

Standard size: 3’-0” x 6’-8” x 1-3/4”

Standard finishes: Birch, maple, oak, and walnut

Door Frame Types

Pre-Assembled Frame

Entire door assembly is shipped to jobsite, reducing door installation time onsite

Knock-Down Frame

Shipped in parts and assembled on-site

Easier to ship and store

Hardware Options

This is a concise overview of the options available for door hardware. Detailed descriptions can be found if you continue scrolling down.

Locks: Lever, mortise, panic bars, keypads, or card readers

Hinges: Plain bearing, heavy-duty ball bearing, or spring-loaded

Closers: Hydraulic or pneumatic for self-closing doors

Thresholds & Weatherstripping: Ensures energy efficiency and environmental protection

Drip caps: Keep rain from falling on your head as you open the door on a rainy day

Door Configurations

Left-hand or right-hand swing

Standard or reverse

Specialty Applications

Need a door to do something a bit out of the normal? Here’s a quick list of the common applications that require a unique door.

ADA Compliance

Fire rating

Texas and Florida Wind Rating

Bullet- and blast-resistant doors and frames

Acoustical or high STC rated doors (sound transmission coefficient)

Odd sized door openings

Specialized access control hardware (i.e. card readers)

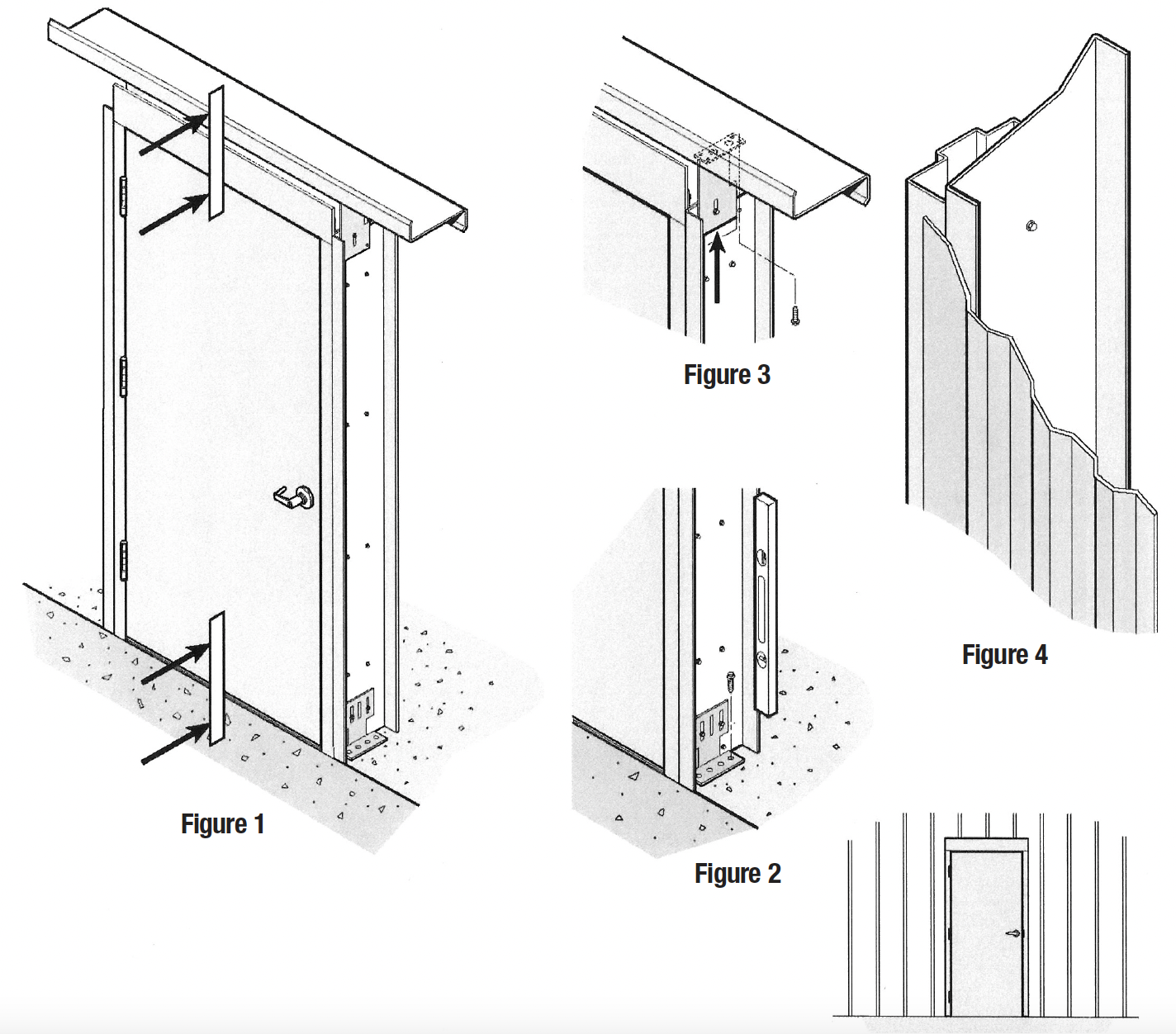

How Do Walk Doors Mount to a Building?

Metal building walk doors are “self-framing” meaning that they don’t require a standard framed opening like a traditional door. If your first girt is located at 7’-4”, this door will bolt right to that girt. If you have a girt above or below the standard 7’-4”, you may require a framed opening to support the intermediate girt and/or provide a header for the door to mount to.

Here’s a great video from EXPI-Door on how to mount a standard door.

How To Choose a Lock

A good lock is your building's first line of defense. The info below will help you select the right lock for your door.

ANSI Grading System

The American National Standards Institute (ANSI) grades locks based on their security level. The ANSI grading system uses three levels:

Grade 1: Highest security level

Typically used in commercial settings or high-security residential

Grade 2: Intermediate security level

Balance security and affordability

Grade 3: Basic security level

Interior doors or areas with minimal security concerns

Lever Locks

Lever locks operate with a key on the outside and a thumb turn or button on the inside. While convenient, these locks don’t offer much security on their own and are typically paired with a deadbolt for additional protection.

Deadbolts

Deadbolts come in two main types:

Single cylinder deadbolts

Most common type of deadbolt

Unlock with a key on the outside and a thumbturn on the inside

Double cylinder deadbolts

Require a key on both sides to provide extra security

Great on doors with glass panels since an intruder can’t smash the glass and open the door

Can slow escape during a fire

Mortise Locks

Mortise locks are some of the strongest locksets available. They feature a spring-loaded latching mechanism and deadbolt in a single rectangular housing. The lock is recessed, or “mortised,” into the edge of the door.

Door Closers

Primary Functions of a Door Closer:

Automatic Closing:

Ensures the door returns to a closed position after each use — ideal for maintaining privacy, security, or climate control.Controlled Motion:

Prevents doors from slamming shut, which can cause noise, damage, or injury.Fire and Smoke Control:

Required on fire-rated doors to ensure they close automatically in the event of a fire, helping to contain flames and smoke.

Here are a few more articles that you may find interesting: